-

Hot

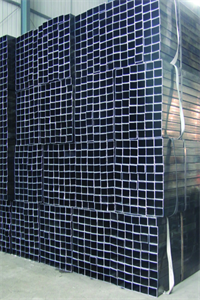

Q195 Cold Rolled steel hollow section Pipes for fence

The cold-rolled welded pipe has high precision, uniform wall thickness, high brightness inside the pipe surface (the surface brightness of the steel pipe is determined by the surface grade of the steel plate), and can be arbitrarily fixed. In high precision, medium and low pressure fluid applications reflect its economy and aesthetics. The main differences between cold rolling and cold rolling are: 1. Local buckling occurs in the section of cold-rolled shaped steel, so as to make full use of the bearing capacity of the bar after buckling; Local buckling of hot rolled section is not allowed. 2. The causes of residual stress in hot rolled steel and cold rolled steel are different, so the distribution on section is also very different. The residual stress distribution on cold-formed thin-wall section is curved, while that on hot-bound or welded section is thin film. 3. The free torsion stiffness of hot rolled section is higher than that of cold rolled section, so the torsion resistance of hot rolled section is better than that of cold rolled section. Standard : GB/T3091-2001 * ASTM A53-1996 * BS1387-1985 * BS4568-1970 * GB/T6728-2002

Send Email Details